Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

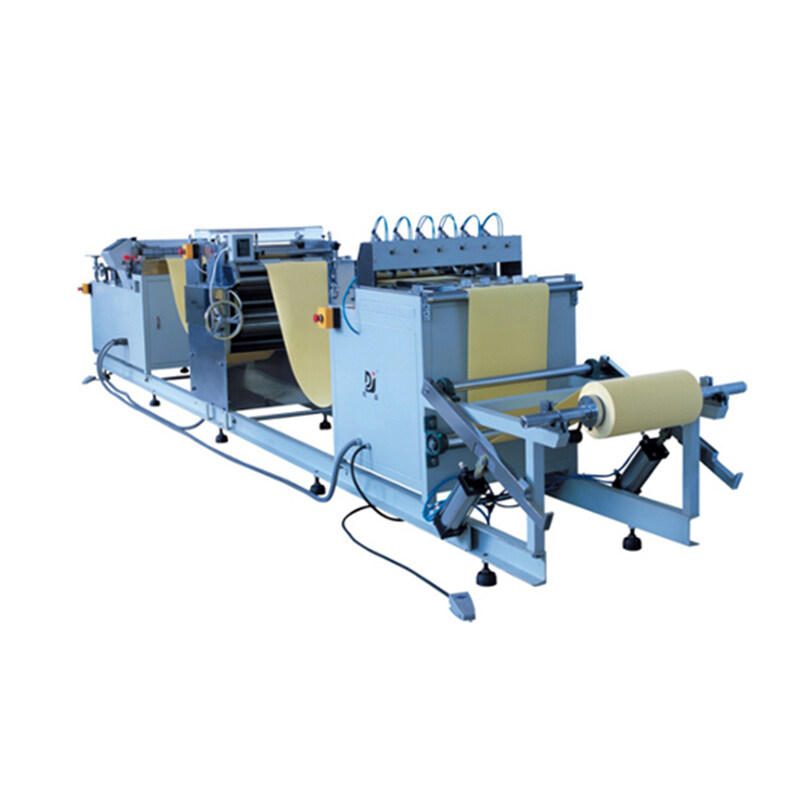

SELQ-80-500 Full-auto Expanded Metal Spiral Core Making Machine

The SELQ-80-500 full-auto expanded metal spiral core making machine is a revolutionary machine that is used to produce heavy duty air filter inner and outer nets directly from metal belts. It combines traditional metal mesh making machine, flattening machine, spot welding machine, and spiral tube making machine into one, making it extremely convenient and easy to operate.

-

Product Details

Product Introduction

This air filter wire mesh spiral core machine is used to directly produce inner and outer meshes of heavy duty air filters from metal belts. The metal strip will be unrolled and flattened before the spiral sewing process. It integrates traditional metal mesh making machine, flattening machine, spot welding machine, and spiral tube making machine. The device has the advantages of compact structure, low power consumption, easy maintenance, and operation.

Specification

1.Diameter range: 100-500mm (inside or outside seaming)

2.Metal strip material: anti-fingerprint/galvanized steel

3.Steel strip thickness: 0.3-0.4mm

4.Steel strip width: 67mm

5.Expanded metal width: 120mm

6.Motor power: 4Kw

7.Power supply: 380V/50Hz

8.Machine weight: 1500kg

9.Machine size: 1800mm*1100mm*1350mm (L*W*H)

Features of Full-auto Expanded Metal Spiral Core Making

1.The machine combines traditional expanded metal mesh making machine, flattening machine, spot welding machine, and spiral tube machine into one.

2.It can expand flat steel strips of a certain width and give them high-density patterns with its unique structure.

3.The total production capacity is up to 4 tons per hour.

4.The device has the advantages of compact structure, low power consumption, easy maintenance, and operation.

5.It can produce steel mesh or spiral lock seam pipes of different widths.

6.Automatic change of pitch angle of roll plane.

7.Precision grinding is optional before sealing the parts.

Advantages of Full-auto Expanded Metal Spiral Core Making

1.The machine saves raw materials and energy consumption, as well as space:

The SELQ-80-500 full-auto expanded metal spiral core making machine is designed to directly produce heavy duty air filter inner and outer nets from metal belts, which reduces the need for raw materials and energy consumption. Additionally, the machine combines traditional metal mesh making machine, flattening machine, spot welding machine, and spiral tube making machine into one, which saves space in the production facility.

2.Environmentally friendly and produces less waste:

The machine’s unique structure allows it to expand flat steel strips of a certain width and give them high-density patterns, which reduces waste in the production process. Furthermore, the machine is designed to be environmentally friendly, making it an ideal choice for companies looking to reduce their carbon footprint.

3.The machine is easy to use and suitable for mass production:

The SELQ-80-500 full-auto expanded metal spiral core making machine is extremely convenient and easy to operate. It can produce steel mesh or spiral lock seam pipes of different widths, and the automatic change of pitch angle of roll plane makes it easy to adjust the machine to meet different production needs. These features make the machine suitable for mass production.

4.It has high production efficiency, low failure rate, small dust pollution, and convenient operation and maintenance:

The machine has a total production capacity of up to 4 tons per hour, making it highly efficient. Additionally, the machine has a low failure rate, which reduces downtime and increases productivity. The machine’s design also minimizes dust pollution, making it a safer and cleaner option for production facilities.