Fuselage Structure Of Car Filter Housing Hydraulic Stretcher

Every car needs a filter to last the life of the car. If you are a filter manufacturer, then the production of the filter housing requires a stretching machine, which needs to be determined according to the production process. As one of the leading China hydraulic stretcher manufacturers, our customers have different needs for hydraulic stretchers. Some customers need multiple machines to complete the stretching process of the filter housing, and vice versa.

Regarding the drawing process of the filter housing, we need to consider the tonnage and fuselage structure. First, let's start with the principle.

The working principle of the car filter hydraulic stretcher

1. Through the upper mold assembly and the lower mold assembly that cooperate with each other, the sheet material can be stretched twice in the same machine.

2. In the initial state, the first stretching power mechanism and the second stretching power mechanism act, so that the top surface of the blanking lower mold, the pressing block, and the first stretching mold (that is, the side facing the upper mold assembly side) surface) is even.

Drawing hydraulic stretcher tonnage and fuselage structure

China hydraulic stretcher manufacturers provide hydraulic stretchers of different tonnages for you to choose from, from 200 tonnage to 500 tonnage.

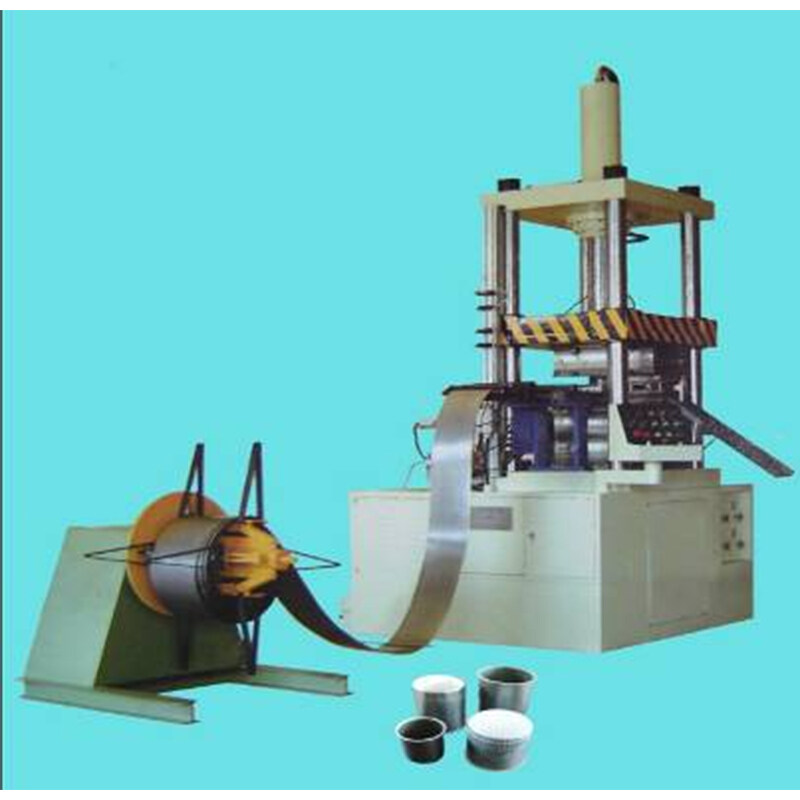

200 tons of four-column hydraulic stretcher

After the sheet is sent to the automobile filter shell stretching hydraulic press, it will fall between the blanking upper die and the blanking lower die. Under the action of the power mechanism of the upper mold, the blanking upper mold moves to the side of the lower mold assembly and touches the sheet first to realize blanking. The sheet material after blanking falls into the blanking hole located in the blanking lower die. Subsequently, the first stretching power mechanism acts, and cooperates with the power press of the upper mold, so that the blanking upper mold is pressed on the pressing stopper, and the sheet material is clamped between the blanking upper die and the pressing stopper. As the blanking upper die continues to move, the blank will be stretched by the first drawing die.

At this time, the first drawing die will be used as a drawing punch, and the blanking upper die will be used as a drawing die. internal. Subsequently, the first stretching power mechanism stops acting, and the second stretching power mechanism acts, so that the plate is clamped between the pressing edge and the pressing block. As the power mechanism of the upper mold drives the upper mold assembly to continue downward, the second drawing die will act as a drawing punch, and the drawing upper die will act as a drawing die, and the sheet material will be processed for the second time along the longitudinal direction of the second drawing die. Stretch and access the inside of the drawing punch.

400 tons of four-column hydraulic press

The hydraulic stretcher provided by Hydraulic stretcher manufacturers can adopt four-column structure or frame structure. Different stretching machines cooperate with special molds to realize stretching, trimming and shaping at one time. The equipment adopts a separate mold, and the required stretching coefficient can be adjusted separately, and the transfer of parts between each process is controlled by the manipulator.

500 tons filter housing stretching hydraulic press

The stretching hydraulic press for the automobile filter shell adopts a three-beam and four-column structure, which is economical, practical, and high in efficiency. The cost of the frame structure is high, and customers can choose the appropriate body structure according to the material of the filter shell (such as stainless steel stretch, cold-rolled sheet stretch, galvanized sheet stretch, iron sheet stretch, etc.). Through the company, the customer is designed into a three-beam and four-column structure. The automobile filter shell stretching hydraulic press is composed of two major parts: the main engine and the control mechanism. The host part includes frame, master cylinder, ejector cylinder and liquid filling device, etc.; the power mechanism is composed of fuel tank, high-pressure pump, low-pressure control system, electric motor, various pressure valves and directional valves, etc. Tensile force and blank holder force are adjustable; high efficiency, low power consumption, low noise; with safety protection device, stable work and convenient operation. It is especially suitable for stretching and flanging of metal sheets, and can also be used for forming cold-extruded metal parts.

China hydraulic stretcher manufacturers can provide you with hydraulic stretchers of different tonnage and precision. If you have difficulty in choosing tonnage and fuselage structure, please do not hesitate to contact us. Runya will provide you with solutions according to your actual situation.